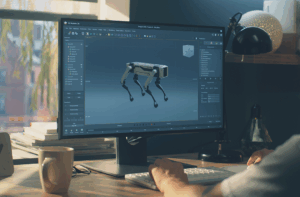

In the manufacturing industry, where cutting-edge designs drive success, your Computer-Aided Design (CAD) files are more than just digital drawings; they’re the embodiment of your intellectual property and future products. Imagine the culmination of countless hours and significant investment—your most innovative designs—suddenly in the hands of a competitor. This isn’t a hypothetical fear for manufacturers; it’s a growing threat. As designs become more complex and collaboration more widespread, your valuable CAD files, central to innovation, are prime targets for cybercriminals and competitors alike. A single data breach can erase years of development and drastically impact your bottom line.

In the manufacturing industry, where cutting-edge designs drive success, your Computer-Aided Design (CAD) files are more than just digital drawings; they’re the embodiment of your intellectual property and future products. Imagine the culmination of countless hours and significant investment—your most innovative designs—suddenly in the hands of a competitor. This isn’t a hypothetical fear for manufacturers; it’s a growing threat. As designs become more complex and collaboration more widespread, your valuable CAD files, central to innovation, are prime targets for cybercriminals and competitors alike. A single data breach can erase years of development and drastically impact your bottom line.

Think about it: your CAD files aren’t just lines and curves on a screen. They represent years of research, development, and investment. They are the digital embodiment of your unique designs, your innovations, and your future products. Letting these fall into the wrong hands can have catastrophic consequences. This challenge is further compounded by the complex realities of modern manufacturing. Engineers and designers often navigate a diverse environment, utilizing various CAD software programs. This diversity can make it challenging to implement consistent and effective security policies across the board. While traditional encryption methods represent a step in the right direction, they often fall short of providing the comprehensive, persistent protection needed throughout the entire lifecycle of a design file. This leaves sensitive information vulnerable at various stages – from initial creation and internal collaboration to external sharing and long-term storage.

This brings us to a critical question: Are you truly securing your CAD data against the evolving threat landscape?

To help you assess your current security posture, let’s dive into the Top 5 Data Security Risks in Manufacturing CAD.

The Top 5 Data Security Risks:

-

The Insider Threat – A Double-Edged Sword:

- The Risk: Whether intentional or unintentional, threats from within your organization pose a significant risk. Disgruntled employees looking to gain an advantage at a competitor, or even well-meaning staff accidentally sharing files, can deliberately exfiltrate valuable design files. As employees leave your company, they may walk out the door with valuable files for their “personal use.” Equally concerning are unintentional breaches caused by negligence – accidentally sharing files, using unsecure personal devices, or falling victim to phishing scams.

- The Takeaway: Your security strategy must account for both malicious and accidental insider actions. Implementing strong access controls, monitoring user activity, and educating employees on data security best practices are crucial.

-

The Perils of Uncontrolled External Sharing:

- The Risk: Collaboration is essential in modern manufacturing. Sharing CAD files with external partners like suppliers and subcontractors is a routine part of the process. However, without robust controls, this sharing can become a major vulnerability, potentially allowing unauthorized access during critical sales processes or collaboration with subcontractors.

- The Takeaway: Implement secure file-sharing protocols with clear authorization workflows and access restrictions. You need to maintain control over who can access your designs and what they can do with them, even after they’ve left your immediate environment.

-

The Blind Spot – Lack of Visibility and Audit Trails:

- The Risk: How can you protect what you can’t see? Without comprehensive tracking of who is accessing, modifying, or sharing your CAD files, you operate in the dark. This lack of visibility makes it incredibly difficult to detect suspicious activity, investigate potential breaches, and understand the flow of your sensitive data. The absence of detailed audit logs hinders any post-incident analysis and makes it challenging to identify the source of a data leak.

- The Takeaway: Implement systems that provide detailed logs of all CAD file activity, including access attempts, modifications, sharing actions, and any policy enforcement events. This audit trail is crucial for security monitoring, compliance, and incident response.

-

The Weak Link – Vulnerability of Unprotected Files:

- The Risk: Relying solely on perimeter security or basic encryption at rest might not be enough. CAD files can be vulnerable throughout their lifecycle. If files are not persistently protected, they can be easily accessed once they leave a secure environment, are transferred via less secure methods, or are opened with different software versions that may not enforce the original security settings.

- The Takeaway: Consider solutions that offer persistent protection, ensuring that security policies travel with the file, regardless of its location or the application used to open it. This ensures your designs stay secure at every stage.

-

The Extended Enterprise – Supply Chain Vulnerabilities:

- The Risk: Modern manufacturing often involves intricate supply chains with numerous external partners. Each entity that gains access to your CAD files represents a potential point of weakness. If your suppliers or other partners have lax security practices, their vulnerabilities can become your vulnerabilities, providing an entry point for attackers to access your valuable design data.

- The Takeaway: Extend your security considerations to your supply chain. Vet your partners’ security practices and explore solutions that allow for secure collaboration without compromising your IP.

Conclusion: Moving Towards Comprehensive CAD Data Security

The challenges outlined above make it clear: a truly comprehensive approach to securing CAD data is essential in the modern manufacturing industry. Basic security measures are simply no longer sufficient to protect against today’s sophisticated threats.

Solutions like Fasoo Enterprise Digital Rights Management (EDRM) offer a robust approach by providing persistent encryption, universal control across CAD programs, complete lifecycle management, granular permissions, and detailed audit trails—all without impacting performance. This ensures that your valuable CAD designs are protected from unauthorized access, misuse, and theft, both within and outside your organization.

Furthermore, integrating Data Detection and Response (DDR) capabilities is crucial for an adaptive security posture. DDR solutions actively monitor data access and usage, enabling real-time detection of suspicious activities and automated responses to mitigate potential breaches. By combining the proactive controls of EDRM with the dynamic monitoring and response of DDR, manufacturers can achieve a truly resilient security framework for their critical intellectual property.

By understanding these top data security risks and embracing advanced security solutions, manufacturers can confidently protect their intellectual property, maintain their competitive edge, and foster secure collaboration in today’s interconnected world. Don’t wait for a data breach to expose your vulnerabilities. Secure your blueprints now—the future of your innovation depends on it.